Metal Core PCB Manufacturing

Metal Core PCBs are also known as MCPCB or Thermal PCB. They are Printed Circuit Boards that have metals as their base material in the heat spreader part of the PCB. They are highly efficient in dissipating heat compared to the Standard PCB, although they also have Standard FR4. In addition to their heat dissipating feature, Metal Core PCBs efficiently cool components and ensure a better overall performance of the components.

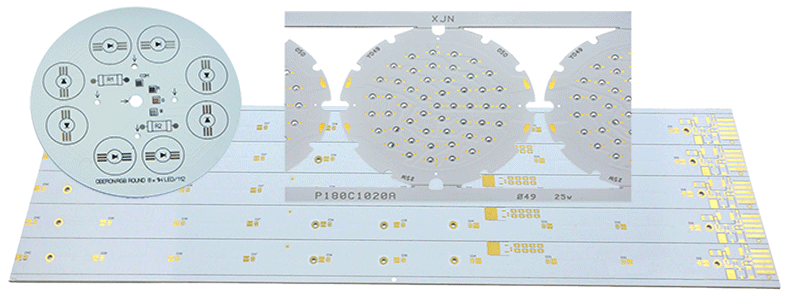

Metal PCBs are made of a Thermal Insulating layer, Metal Plate and Metal Copper Foil. Based on the type of metal core, there are three kinds of Metal PCB. These are Aluminium PCB and Copper PCB, or an alloy of both Copper and Aluminium. However, the most common Metal Core PCB is Aluminium Metal Core PCB due to its effectiveness and low cost. PCBdoing specialises in the production of all varieties of MCPCBs from Aluminium to Copper to Single Side MCPBC to 2-layer MCPCB.

Application of Metal Core PCB

Metal Core PCBs have been widely used in various applications. Mostly used to increase efficiency in heat-generating applications, metal-based PCBs are used in

LED Applications such as Streetlight, Back light Unit and general lighting applications

Power Converters

Electric Motor Control Applications

Audio Frequency apparatus

Communication equipment

Photo Voltaic Applications

Solar Panels and a host of other applications

Why Choose PCBdoing

Top Manufacturer: PCBdoing has been manufacturing Metal Core PCBs for more than 10 years. Hence, we are experts in their production. With experienced experts who are the best in the industry, you can be assured of Metal Core PCBs that suit your requirements.

Quality Metal Core PCBs: Both our Aluminium MCPCB and Copper MCPCB have been widely used in the electronics industry in the manufacture of LED lightings and other applications. We are trusted and tested in the manufacture of quality products. We can guarantee you the very best.

Affordable Prices: Getting your Metal Core PCB from PCBdoing ensures that you save cost of production while also ensuring that the highest quality is maintained.

Get Your Free Quotation Now!

To get your quotation, upload your PCB design file so we can give you the best prices. If you have any enquiries bordering on other things such as Custom Project or our manufacturing capabilities, you can contact us and we'll get back to you as soon as possible!

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 4 - 24layers |

| Order Quantity | 1pc - 10000+pcs |

| Build Time | 2days - 5weeks |

| Material | Aluminum core (Domestic 1060), Copper core, FR4 covering |

| Board Size | Min 6*6mm | Max 610*610mm |

| Board Thickness | 0.8mm - 5.0mm |

| Copper Weight (Finished) | 0.5oz - 10.0oz |

| Min Tracing/Spacing | 4mil/4mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL - Hot Air Solder Leveling Lead Free HASL - RoHS ENIG - Electroless Nickle/Immersion Gold - RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

| Other Techniques | Countersink holes Screw holes |